Back to lab overview

Back to lab overview

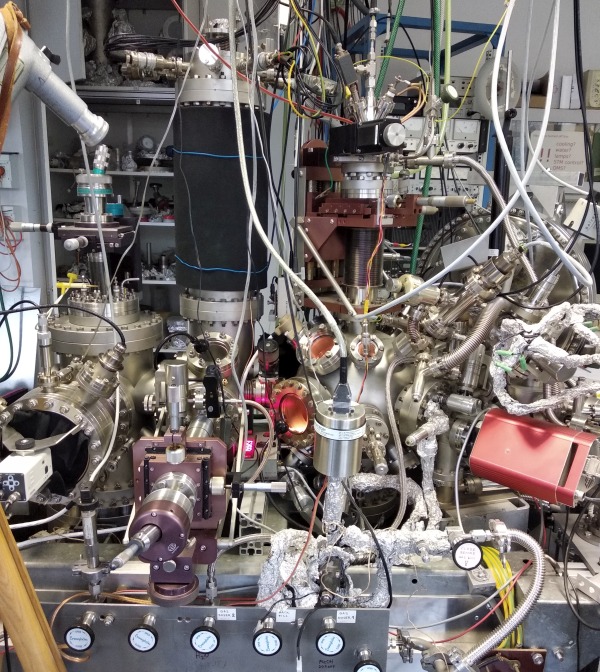

STM-XPS-TPD-LEED UHV system

- Basic description: UHV system for model studies of surface structure and reactivity relationships

- Techniques and capabilities: XPS with dual Al/Mg X-ray source, LT STM, differentially pumped QMS with 2 effusive milecular beams, back-view LEED, in-situ electrochemical cell

- Purpose: Interaction of gas molecules with surfaces and catalytic reactions in UHV conditions, study of struture-reactivity relationships. Samples are prepared in-situ and characterised by XPS. Adsorption properties of surfaces and their reactivity are studied by TDS and MB. Surface structure of oriented samples is characterized by LEED.

- Manager: J. Mysliveček

- Team: J. Mysliveček, V. Johánek, L. Fusek, P. Samal, J. Škvára

Experimental methods:

- STM: Custom made scanning tunnelling microscope with LN2 cooling capability.

- XPS: X-ray photoelectron spectroscopy system, based on a Hemispherical Electron energy Analyser Omicron EA 125 and a Dual-anode X-ray source. Enables studying the detailed chemical composition of surfaces (qualitative, quantitative and chemical analysis, electron structure of surface, adsorbed species)

- TPD/TPR, MB: Thermally-programmed desorption and reaction (TDS, TPR) spectroscopies built on two effusive molecular beams and differentially-pumped Quadrupole Mass Spectrometer (QMS) enable to study interaction of molecules with sample surface or reactivity of the surface in real time and in dependence on temperature.

- LEED: Low Energy Electron Diffraction with rear-view optics, placed in a separate connected chamber, enables to check the geometrical structure of surface.

- EC cell: Unique custom made electrochemical cell for model in-situ EC studies.

Further equipment:

- Ion guns: one for sample cleaning, one for LEIS (differentially pumped with scanning feature)

- Evaporators: Several e-beam evaporators for different metals (Pt, Pd, Ce, Co, Sn, ...) are used to prepare well defined samples in-situ. Growth of other compounds (e.g. metal oxides) is possible in reactive environments.

- Gas line: Gas dosing system with several parallel lines - back-fill inlets, 2 effusive gas beams (one of them with automatic pressure control).

Problems under study:

- Metal thin film growth and reconstruction (Pt, Pd, Rh, Ce, Co, Cu, bimetallic systems, ...)

- Interaction of metal thin films with substrates (CeO2, CoOx, Al2O3, SnO2)

- Molecule adsorption (CO, O2, H2O, methanol etc.) and surface reaction

- Electronic system of studied samples

- Properties of model catalysts – structure, reactivity, stability, metal-support interactions